Servi-tech offers powerful and robust yet precise and flexible automation solutions that allow innovations to be scaled quickly, efficiently and profitably. For cleanroom environments, clean robots meet the healthcare industry’s processing equipment specifications for accuracy, consistency and cleanliness, making them ideal for a wide range of assembly, dispensing, inspection and material handling applications.

Closing Productivity Gaps, Enhancing Outcomes

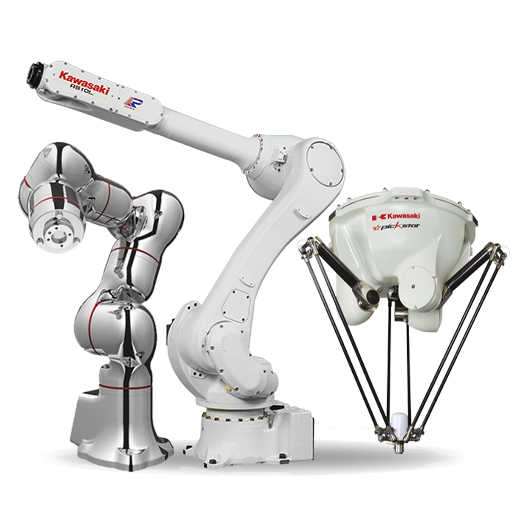

Kawasaki’s 6- and 7-axis robots can carry payloads of between 2 kg and 1,500 kg, making them suitable for packing and dispensing medication as well as manipulating bulky liquid containers during large-scale pharmaceutical compound production.

Medical device manufacturing robots assembling

Robots can assemble complex medical devices with high precision and repeatability. This is especially important for devices that are implanted in the body, where even a small defect can have serious consequences.

Medical device manufacturing robots inspection

Robots can be equipped with vision systems to inspect medical devices for defects. This can help to ensure that only high-quality devices are released to the market.

Medical device manufacturing robots packaging

Robots can package medical devices in a sterile environment. This is important to prevent contamination of the devices

Robots can move materials around the manufacturing facility, which can free up human workers to perform other tasks.